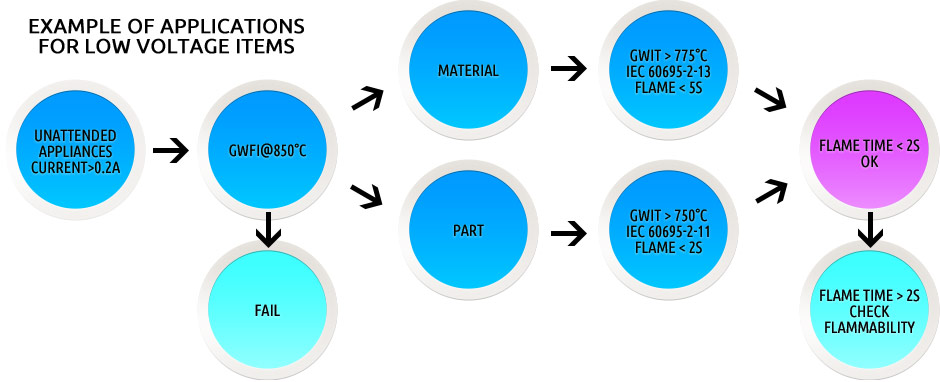

Organisation of the fire tests protocol according to the Low voltage directive 2006/95/CE

The regulation concerning the electrical and electronic material involves the material assessment for their fire behavior. The CREPIM is accredited by the COFRAC to lead some of the tests for this kind of application. The different tests in relation with this field are the following ones:

Allumability / self-extinguishing test

NF EN ISO 60695-10-11 - UL 94

These standards refer to different sub-tests allowing the classification of materials according to the results of these tests.

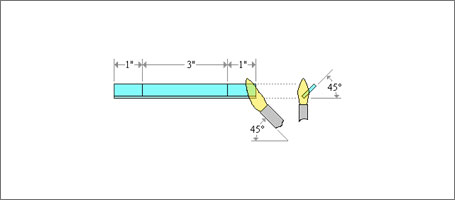

Horizontal flame propagation test: Classification UL 94: HB, HB 40 et HB75

This fire test consists in putting the material horizontally under a 500W flame to assess its fire behavior for the horizontal propagation. Thus, a propagation speed can be measured. The classification depends on the measured speed.

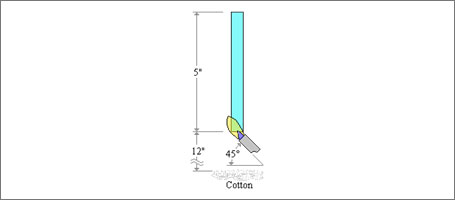

Vertical flame propagation test: Classification UL 94 V0, V1 et V2

This fire test consists in putting the material vertically under a 500W flame to assess its fire behavior for the flame persistence and thus for the self-extinguishing. Moreover, the fall of burning fragments is checked during the all test. Flame persistence and glowing duration when the burner is taken away, the flame vertical propagation and the fall of droplets which cause or not the ignition of the cotton under the sample allow the material classification.

- The flame persistence times after removal from the burner and

- the incandescence times after the flame has been extinguished,

- as well as the vertical propagation of the flame and the fall of the drop,

- whether or not igniting a cotton pad located under the test specimen.....allows the classification of the material.

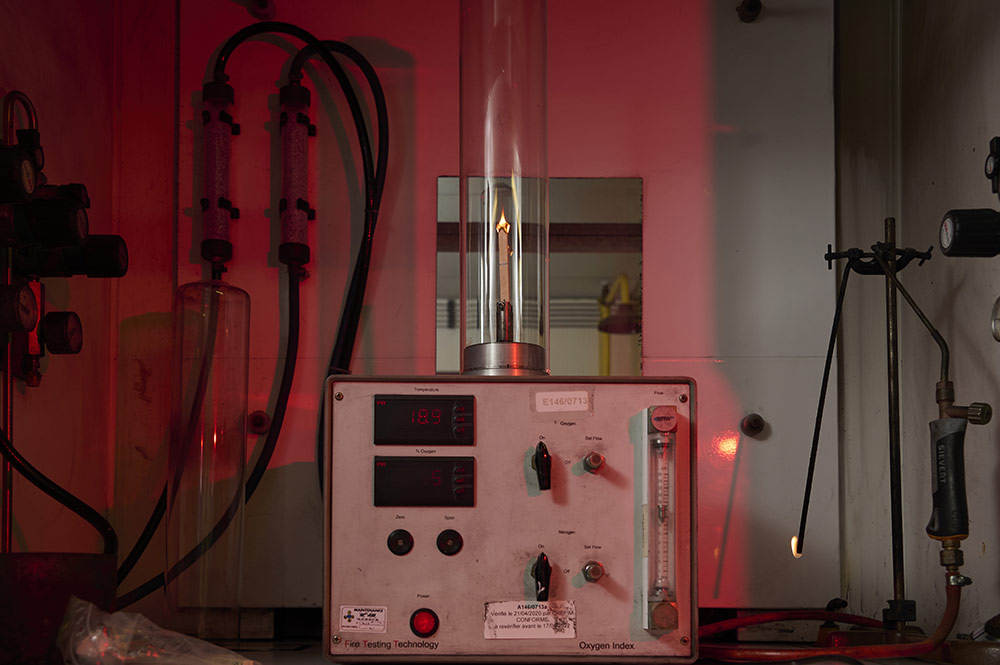

ISO 4589-2 : Determination of the limit oxygen index

This fire test leads to the determination of the minimal oxygen concentration, in addition with nitrogen, which will support the combustion of small vertical samples under some specific conditions. This fire test is realized at an ambient temperature of 23°C ± 2°C. Results are defined as limit oxygen index (LOI).

Principle : A little sample is hold horizontally in an atmosphere mixing oxygen and nitrogen in a transparent chimney. The superior extremity of the sample is ignited and the fire behavior is recorded to compare the combustion duration, the burned length and the specific limits of this combustion. By testing several samples in atmospheres composed by different oxygen concentrations, it is possible to determine the limit oxygen index.

Allumability fire test – NF EN 60695-2-10/11/12 – Glow wire test dedicated to ignition time and flaming persistence measurment

This test simulates, for instance, an electrical or electronic surge on electronic cards. Indeed, the glow wire allows a really local application (on few millimeters) with real high temperature (up to 960°C).

The principle is to apply, for 30 seconds, the glow wire on a material to assess the combustion duration, the flame persistence after the withdrawal of the wire and the presence or not of fragments fall (burning or not).

.

The wire temperature can vary from the ambient temperature to 960°C allowing the determination of parameters as the GWFI one or the GWIT one or to validate the behavior at a given temperature (750°C, 850°C …).