Organisation of the fire tests for Aircraft according to FAR/CS 25

Fire/smoke regulation in the aircraft field is global and has existed for several years. This regulation is international and uniform.

There are 2 standards which are, in practice, equivalent:

- La « Federal Aviation Regulation » ou FAR pour le territoire US

- The «Certification Specifications for Large Aeroplanes» CS In Eu territory

The CS-25 « Certification Specifications for Large Aeroplanes » features a complete list of requirements

- CS 25.853 Compartment interiors

For each compartment occupied by the crew or passengers :

- (a) Materials must meet App. F part 1

- (b) Seat cushions (except flight crew), must meet App. F part I & II

- (c) For aeroplanes with passenger capacities of 20 or more

- Interior ceiling and wall panels , partitions, and the outer surfaces of galleys, large cabinets and storage compartments

- Must also meet App. F Parts IV and V - FAR/CS 25.853 Fire test to aircraft material - Test method

- Vertical flammability test: 14 FAR 25.853 b(4)), (App. F to part 25 part I § (a)

- Horizontal Test: 14 FAR 25.853 b(2,3), (App. F to part 25 part I § (a),(1)

- 45° flammability test: 14 FAR 25.853 (b), (App. F to part 25, part I § (6))

- Heat Release Test: 14 FAR 25.853 (d), Appendix F, Part IV

- Seat Test: 14 FAR 25.853 (c, App.F to part II)

- Smoke Density Test: 14 FAR 25.853 (d), (App. F to part 25, part V) - CS 25.854 Lavatory fire protection

- CS 25.853 Cargo or baggage compartments

- CS 25.856 Insulation materials

(a)Thermal/acoustic insulation material installed in the fuselage must meet the flame propagation test requirements of part VI of Appendix F

(b)For airplanes with a passenger capacity of 20 or greater, thermal/ acoustic insulation materials (including the means of fastening the materials to the fuselage) installed in the lower half of the airplane fuselage must meet the flame penetration resistance test requirements of part VII of Appendix F - CS 25.857 Cargo compartment classification

- CS 25.869 Fire protection : systems

(3) EWIS components must meet the requirements of §25.1713 - CS 25.1713 EWIS (Elec Wiring Interconnection System)

(c) Insulation on electrical wire and electrical cable installed in any area of the aeroplane must be self-extinguishing when tested in accordance with the applicable portions of Part I, Appendix F. - CS 25 Appendix F - list of FR test

| Appendix F | ||

|---|---|---|

| Part | Details | Kind of test |

| I | fire Test criteria and procedures for showing compliance with CS 25.853 or 25.855 | Bunsen burner |

| II | Flammability of seat cushions acc. to 25.853(b) | Oil burner |

| III | Resistance to flame penetration of cargo lining | Oil burner |

| IV | Heat Release Rate from cabin materials exposed to radiant heat and flame | OSU chamber Heat release |

| V | Smoke emission characteristics of cabin materials exposed to radiant heat and flame | NBS chamber Smoke emission |

| VI* | Resistance to Flame Propagation of insulation materials | Radiant panel |

| VII* | Resistance to Flame Penetration of insulation materials | Oil burner |

CREPIM is well equipped to realize principal tests according to FAR 25.853. The most majority of our tests in this area are realized under COFRAC accreditation.

The tests which can be led in the CREPIM are the following ones:

Allumability test: FAR 25.853 (a) - FAR 25.853 (b)

Allumability test – 60 s with a vertical burner – (FAR 25.853 (a))

Allumability test – 12 s with a vertical burner – (FAR 25.853 (b))

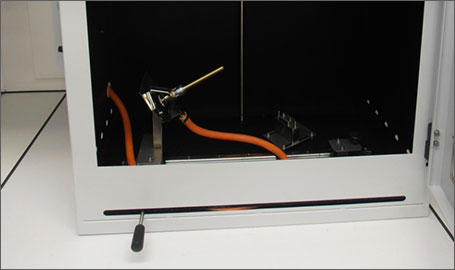

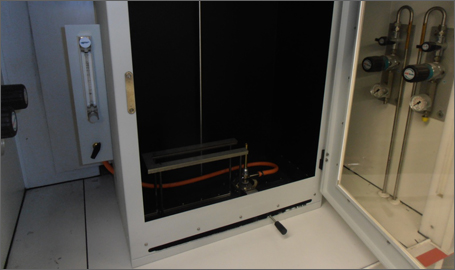

In this fire test, a flame is applied to the sample, which is in a vertical position, to assess the fire behavior of the material for a flame application time of 12 or 60 seconds. The recording parameters are:

- The flame persistence time when the burner is taken away

- The burned distance

Allumability test - FAR 25.855 (a)

30 s with a burner at 45° – (FAR 25.855 (a))

This fire test consists in the application of a flame on a sample at 45° to assess the fire behaviour of the material for a flame application time of 30 seconds.

The recording parameters are:

- The flame persistence time when the burner is taken away,

- The glowing time after the flame extinction,

- The material drilling by the flame.

Flame Propagation test - FAR 25.853 (b-2), FAR 25.853 (b-3)

Propagation test – Speed < 64 mm/min (2,5 inches/min) – (FAR 25.853 (b-2))

Propagation test – Speed < 102 mm/min (4 inches/min) – (FAR 25.853 (b-3))

The aim of this fire test is to apply a flame to a sample in a horizontal position to assess the flame propagation speed on the material. Two speed criteria exist according to the final use of the product in the aircraft binnacle.

The propagation speed is measured thanks to 2 landmarks on the sample.

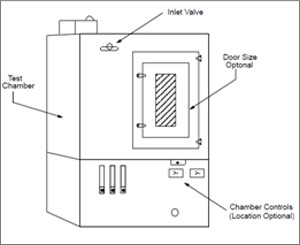

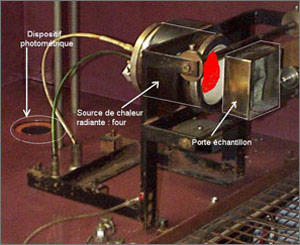

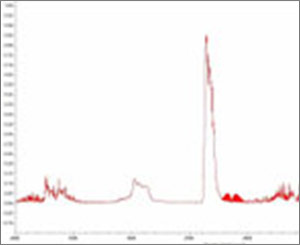

Smoke opacity (FAR 25.853 (Part V) / BSS 7238) & Smoke toxicity (BSS 7239)

This fire test allows the simultaneous measurement of the release smoke quantity dispersed in a fixed air volume by a material under a radiant heat source and the toxicity of the gaseous effluents

The opacity is recorded by the transmission of a light beam inside the chamber throughout the period of test and the relevant parameter is a maximal specific density or Dm. The maximum tolerated Dm depends on the final use of the product and can varies from 100 to 200.

The smoke density is measured thanks to Fourrier transformed infra-red (FTIR) with a gas cell. The sample is directly taken inside the smoke chamber when the measured density is maximal. The measured gases are: HF, HCl, HCN, SO2/H2S, NO/NO2 and CO.